Rebonded Electrically Fused Magnesia Chrome Brick production process:

Fused magnesia-chrome brick is a kind of high temperature refractory, which is mainly composed of magnesia and chromium oxide. The following is the production process of fused magnesia-chrome brick:

1. Raw material preparation: prepare magnesia and chromium oxide powder according to formula requirements. Magnesia should have high purity and fineness to ensure the fire resistance of fused magnesia-chrome bricks.

2. Mixing: the powder of magnesium oxide and chromium oxide is mixed evenly according to a certain proportion. During the mixing process, attention should be paid to controlling the humidity and temperature of the powder to avoid caking or powder moisture absorption.

3. Molding: the mixed powder is put into the mold and formed by pressing. The forming pressure and time need to be controlled according to the specific requirements to ensure the compactness shape of the forming body.

4. Pre-firing: the formed green body is put into a pre-fired kiln for pre-firing. The purpose of pre-firing is to burn out impurities such as moisture and organic matter to improve the mechanical strength of the molded green body.

5. Drying: the pre-fired green body is put into a tunnel kiln for electrofusion. The green body is heated to a high temperature, so that magnesium oxide and chromium oxide are melted and mixed evenly.

6. Cooling: the fused green body is removed from the electric furnace for natural cooling or rapid cooling by controlling the cooling rate. Care should be taken to prevent cracks caused by thermal stress in the cooling process.

7. Inspection: quality inspection of fused magnesia-chrome bricks, including appearance quality, dimensional accuracy, fire resistance and other indicators.

8. Packaging and storage: qualified fused magnesia-chrome bricks are packed and stored in a dry and ventilated warehouse to prevent moisture absorption and damage.

The above is the production process of fused magnesia-chrome brick. By controlling the process parameters of each link, the fused magnesia-chrome brick wi

Introduction to the application of fused rebonded magnesia-chrome brick:

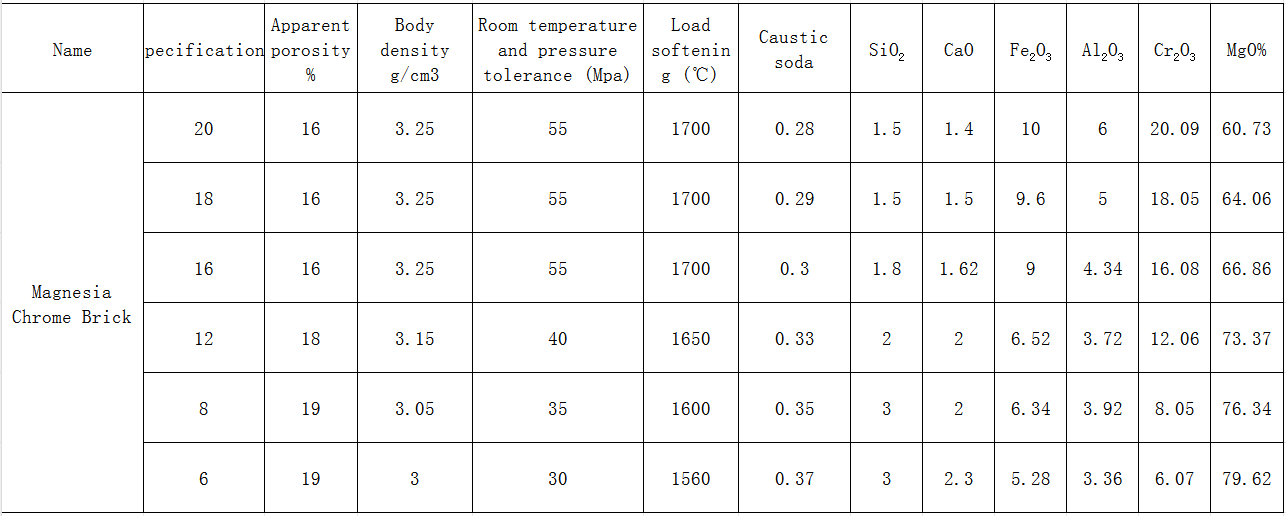

Fused rebonded magnesia-chrome bricks are mainly used in RH furnace, Refining furnace bricks outside the furnace, RH refining unit, non-ferrous metal smelting furnace and other places.

Fused rebonded magnesia-chrome brick is a kind of high temperature refractory, which is widely used in high temperature industry. Used in the lining and protective structure of all kinds of high temperature equipment, it can withstand the erosion of high temperature and corrosion medium, and improve the service life and working efficiency of the equipment.

About us:

The magnesia-chrome refractories used in the RH refining plant developed by our company have high purity, high fire resistance and good thermal shock stability, which is suitable for large and medium-sized and silicon steel RH refining plants. The project has been tested in the RH silicon steel refining plant of WISCO, and the test life has been increased by 20%. In 2017, the project is participating in the China scientists Forum and the second prize for independent innovation.