Production process of Magnesia Chrome Brick:

Magnesia Chrome Brick is a kind of refractory made from magnesia-chrome ore.

Magnesia and chromite are mixed with other materials, usually adding appropriate binders and binders to improve the strength and fire resistance of bricks.

The mixed ingredients are put into the press for pressing and forming, so that it becomes a brick with a certain shape and size. The formed bricks are put into the drying chamber for drying to remove moisture and volatiles and improve the stability and fire resistance of bricks.

The dried bricks are sintered in a high temperature kiln to make the particles combine more closely and improve the strength and fire performance of the bricks.

Inspection quality: carry on the quality inspection to the fired brick to check whether its appearance, size, strength and other indexes meet the requirements.

Packaging factory: qualified bricks are packaged and left the factory for transportation and use.

The above is the general magnesium-chrome brick production process, the specific production process will vary according to different manufacturers and product requirements.

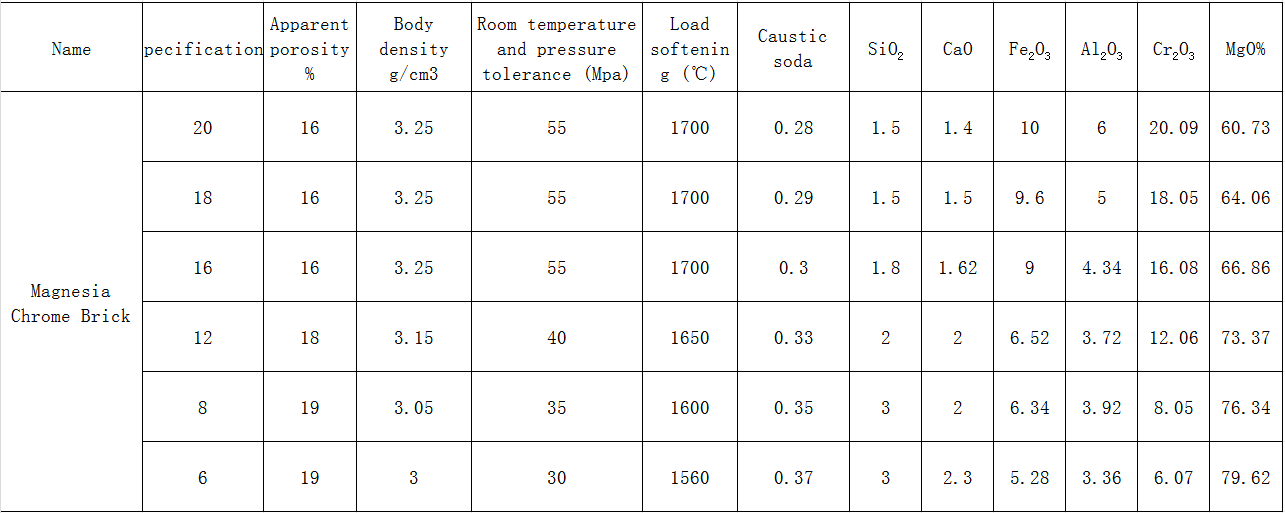

The parameters of magnesia-chrome brick are as follows:

Uses of magnesia-chrome bricks:

Magnesia-chrome brick is a kind of high temperature refractory, which is mainly used for lining and thermal insulation of high temperature industrial equipment. Here are some common uses:

1. Steelmaking electric lining furnace bricks: Magnesia-chrome bricks can withstand high temperature environment and are used to lining various high temperature industrial furnaces, such as metallurgical furnaces, glass furnaces, steel furnaces, etc.

2. Nonferrous metal furnace bricks: Magnesia-chrome brick can be used in the lining of electric furnace, such as electric arc furnace, induction furnace and so on.

3. Environmental protection equipment lining: Magnesia-chrome brick has the characteristics of acid and alkali corrosion resistance, which can be used in the lining of environmental protection equipment, such as acid-base waste gas treatment equipment.

4. Bricks for cement rotary kiln: Magnesia-chrome brick can be used in kiln lining, such as cement kiln, gypsum kiln and so on.

In a word, magnesia-chrome bricks are widely used in high temperature industry, which can provide fire resistance, high temperature resistance and corrosion resistance, and protect the normal operation of industrial equipment.

About us:

On October 26, 2022, Dean Ding, Director Chen, Director Liu of Municipal Bureau, Director Li and Director Wen of County Bureau came to the scene to find problems and put forward rectification and reform suggestions and construction contents in time, so as to make orderly and comprehensive progress in the construction of green mines in our company. To inspect and guide green mine construction projects. With the strong support of leaders and competent departments at all levels of the province, city and county, the construction of green mines has stepped onto a new level, gradually promoted and developed with high quality.