Production process of Alumina (Magnesia-Alumina) Spinel Brick:

Magnesia-alumina spinel brick is a kind of high temperature refractory, which is widely used in metallurgy, chemical industry, building materials and other industries. The production process mainly includes the following steps:

Mix the required raw materials such as alumina and magnesia evenly according to certain examples.

The ground powder is mixed with a certain proportion of binder, and then pressed through the mold to form the required bricks or materials.

The formed bricks or plates are put into the drying chamber to gradually lose moisture and improve their strength and fire resistance by controlling temperature and humidity.

The dried bricks or plates are sintered in a high temperature furnace. In the process of sintering, the crystal structure is changed, the dense structure is formed and the fire resistance is improved by controlling the temperature and keeping it for a certain time.

Carry on the quality inspection to the sintered products, including appearance quality, dimensional accuracy, fire resistance and so on. Qualified products are sold or used in related projects after packaging.

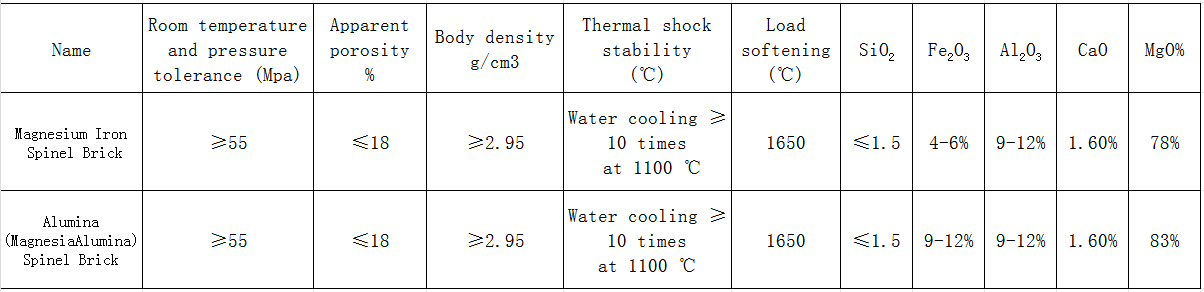

The parameters of magnesia-alumina spinel brick are as follows:

Alumina (Magnesia-Alumina) Spinel Brick usage:

Alumina (Magnesia-Alumina) Spinel Brick is widely used in various fields because of its excellent fire resistance and chemical stability.

1. Metallurgical industry: Alumina (Magnesia-Alumina) Spinel Brick can be used for lining and covering of high temperature smelting equipment such as Bricks for non-ferrous metal smelting furnaces, and can withstand high temperature and corrosive gas erosion.

2. Alumina (Magnesia-Alumina) Spinel Brick in building materials industry can be used for lining and covering of high temperature kilns such as cement kiln bricks, lime kiln bricks and ceramic kilns. It can withstand the erosion of high temperature and melts.

3. Power industry: Magnesia-alumina spinel brick can be used in the lining and cover of high temperature equipment such as boiler, combustion chamber, flue and so on in thermal power plant. It can withstand the erosion of high temperature and combustion products.

In addition, Alumina (Magnesia-Alumina) Spinel Brick can also be used for the maintenance and transformation of some special high temperature equipment.

About us:

After half a year of preparation, Liaoning Wancheng magnesium Group Co., Ltd. officially launched the annual production line of 60, 000 tons of chromium-free new materials on July 18, 2023, covering an area of 37000 square meters and a construction area of 27000 square meters. At present, the main plant and ancillary facilities have been completed, tunnel kilns and other production equipment are being installed one after another, and formal production is expected to be completed by the end of 2023.