Production process of directly bonded magnesia-chrome brick:

Direct bonded magnesia-chrome brick is a kind of high temperature refractory, which is mainly made of high purity magnesia sand and chrome sand as raw materials. Mix the raw materials according to a certain proportion, put the mixed materials into the brick mold, and use vibration or pressure to make them fully dense to form the desired brick shape. Put the formed bricks into the drying chamber for proper drying to remove moisture. Then, the bricks are put into a tunnel kiln and sintered at high temperature so that the binder in the material is pyrolyzed and the ore particles are combined to form a solid brick body.

After the sintering is completed, the brick is removed from the sintering furnace and the temperature is gradually reduced after cooling treatment. The bricks are then packed for storage and transportation.

It should be noted that the specific production technology of magnesia-chrome bricks may vary according to different manufacturers and product requirements, and the above is only a general production process. In the actual production, according to the material characteristics and product requirements, the process parameters need to be adjusted and optimized to ensure the production of high-quality magnesia-chrome bricks.

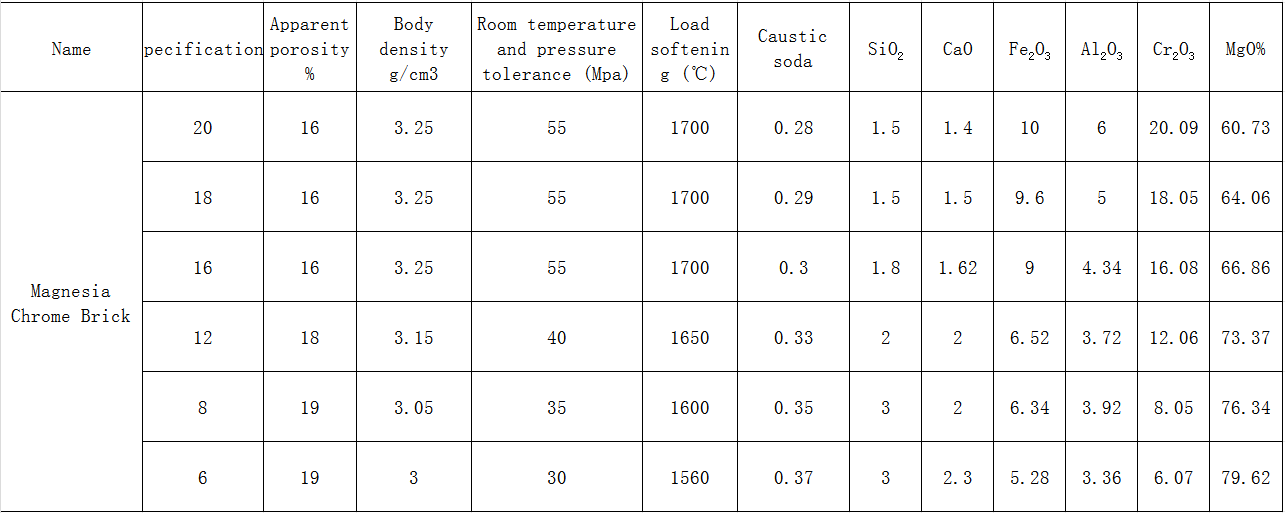

Characteristics of directly bonded magnesia-chrome brick:

The difference between Magnesia chrome brick and directly bonded magnesia-chrome bricks lies in the purity of raw materials and firing temperature. The sintering temperature of ordinary magnesia-chrome brick is 1550 ℃-1600 ℃, and the sintering temperature of directly bonded magnesia-chrome brick is above 1700 ℃. Because the microstructure of magnesia-chrome brick changes when the temperature is above 1700 ℃, magnesia and chromite are directly combined, so it is called directly bonded magnesia-chrome brick.

Characteristics and uses of directly bonded magnesia-chrome bricks:

Direct bonded magnesia-chrome brick is a kind of material composed of magnesium and chromium, which has high fire resistance and corrosion resistance. Direct combination of magnesia-chrome brick refers to the use of magnesia-chrome in combination with other materials or processes to meet specific needs or effects.

For example, in the lining materials of high temperature furnaces, magnesia-chrome bricks can be used as the main materials, combined with other refractories, such as high alumina bricks, aluminum silicate bricks, etc., to enhance the overall fire resistance and corrosion resistance.

It can also be used as a Masonry steelmaking open hearth bricks.

In addition, directly bonded magnesia-chrome bricks are also combined with other materials, such as using magnesia-chrome bricks as fire insulation layer in reinforced concrete structures to improve the fire resistance of buildings.

In short, the combined direct magnesia-chrome brick can be combined with other materials to improve the performance of the material or to meet specific needs.