Brief introduction of production process of Magnesia-Zirconium Brick:

Magnesia-zirconium brick selects high-purity magnesium powder and zirconium powder as the main raw materials, and controls its proportion according to the formulation requirements.

Magnesium powder and zirconium powder are mixed in a certain proportion, and the mixed powder is molded by a press. The formed brick blanks need to be dried to remove moisture, and the dried brick blanks are put into a tunnel kiln for sintering. The sintering temperature and time are controlled according to the specific formula and product requirements.

It should be noted that the specific production process will vary according to the requirements of different manufacturers, the above is for reference only.

The purpose of Magnesium zirconium brick:

Because of its special performance, Magnesium zirconium brick is widely used in the following areas:

Magnesium zirconium brick can be used as lining material of high temperature kiln, such as Glass kiln regenerative bricks, ceramic kiln, steelmaking furnace, etc., which can withstand thermal shock and chemical corrosion in high temperature environment.

Magnesium zirconium brick can be used as high temperature thermal insulation material, such as the thermal insulation layer of high temperature kiln and thermal equipment, which can reduce the heat conduction loss.

Generally speaking, magnesia-zirconium bricks are widely used in high temperature industry, which can meet the requirements of stability, corrosion resistance and thermal insulation in high environment.

Advantages of Magnesia-Zirconium Brick:

Compared with the matrix magnesia brick in the glass industry, the magnesia-zirconium brick produced by Wancheng refractory has higher load softening temperature, good thermal shock stability, especially resistance to alkali vapor permeability and repeated condensation evaporation. In addition, it has good thermal conductivity.

About us:

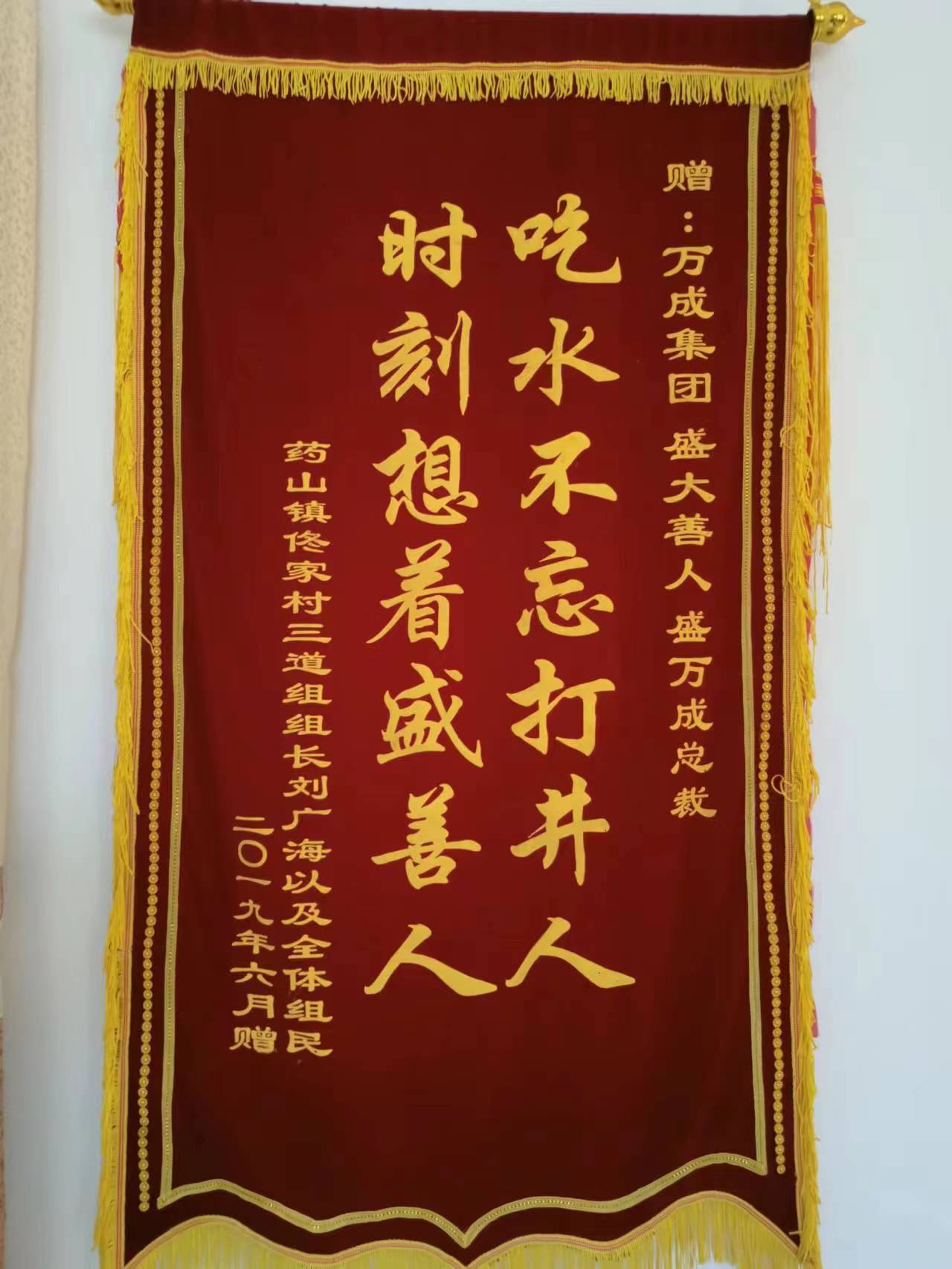

In June 2019, the group company donated 100000 yuan to Tongjia Village, Yaoshan Town, and drilled three deep water wells for the villagers, which solved the local villagers' problem of draught for many years. For this reason, the villagers specially sent brocade flags to express their gratitude.