Production technology of 95% light-burned magnesium powder:

95% of the light-burned magnesium powder uses high-purity magnesia ore as the raw material, and the pretreated magnesium ore is roasted at high temperature to produce magnesium oxide and carbon dioxide after high temperature, and the roasted light-burned magnesium powder is ground to obtain fine-grained light-burned magnesium powder. After grinding, the lightly burned magnesia powder is screened to remove large particles and impurities. The above is the production process of 95% lightly burned magnesia powder. The specific process may be different, depending on different manufacturers and process requirements.

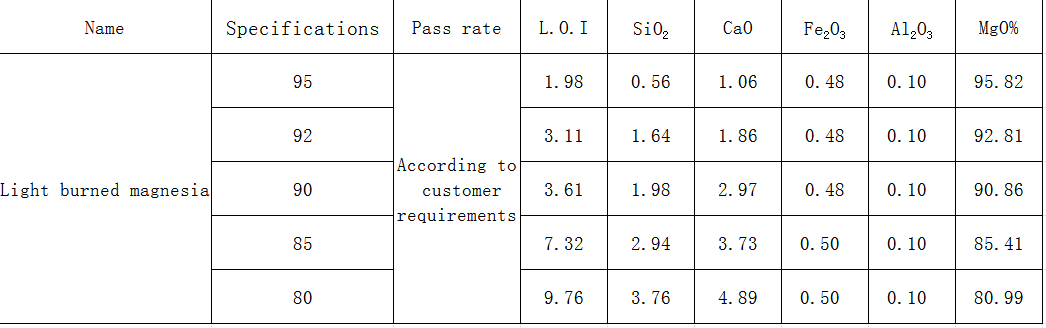

The parameters of lightly burned magnesia powder are as follows:

95% of the main uses of lightly burned magnesia powder:

Fireproof materials: 95% of the lightly burned magnesia powder has good fireproof performance and can be used as the main component of fireproof materials. Can be used in the manufacture of fireproof coatings, fireproof boards, fireproof adhesives and other products.

Eco-environmental protection materials: 95% of the lightly burned magnesia powder is used to make environmentally friendly materials, such as environmentally friendly ceramics, environmentally friendly coatings and so on. Because of its non-toxic, harmless and degradable characteristics, it can reduce the pollution to the environment.

Metal alloy additive: 95% light-burned magnesium powder can be used as an additive of metal alloy, which can improve the properties, strength, hardness and corrosion resistance of the alloy.

ABOUT US:

The elite team of our company is loading and delivering goods for customers, and the goods have been accurately measured and loaded to ensure that they are in good condition in the course of transportation. We will arrange the best transportation plan for our customers to ensure that the destination is delivered on time and safely.