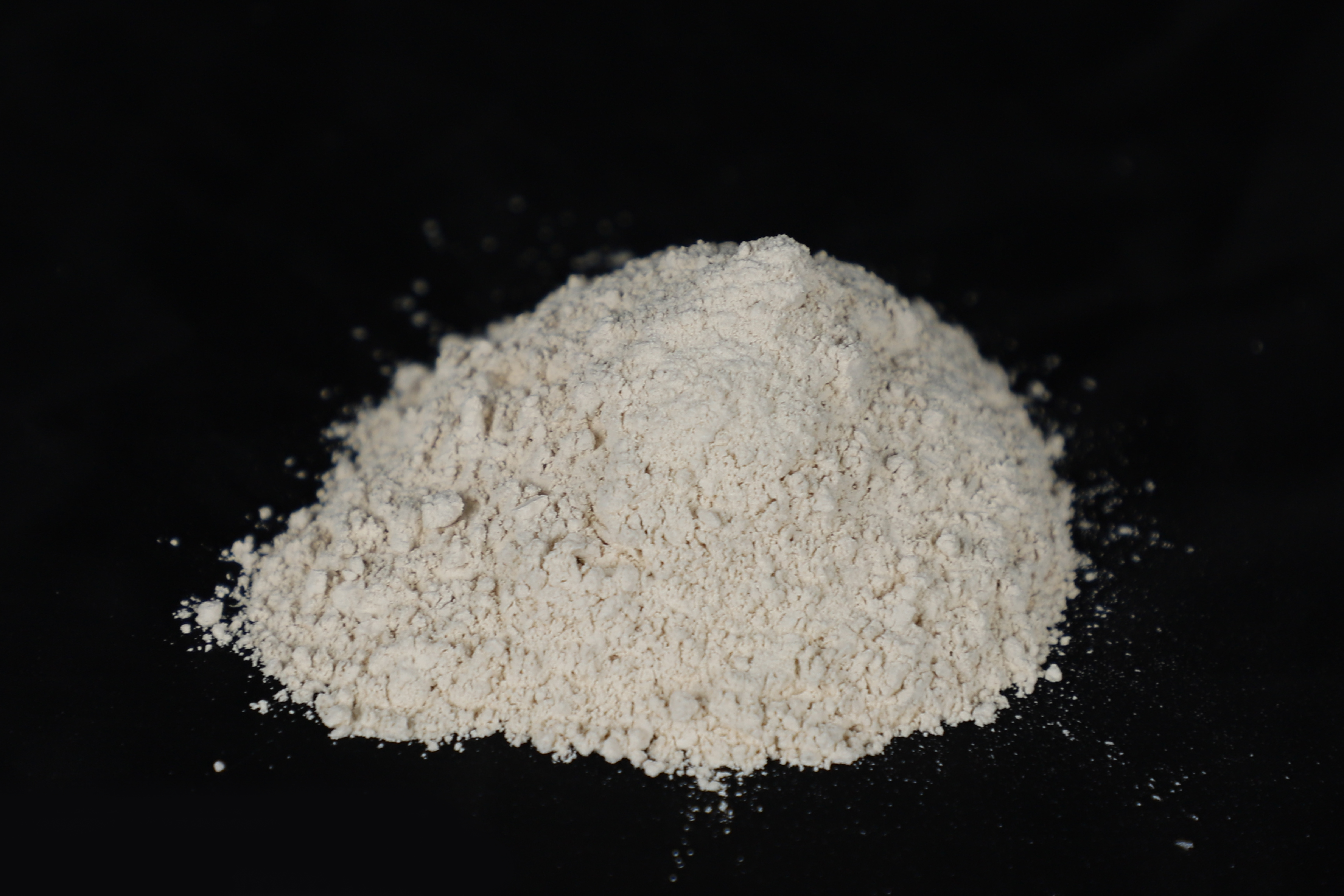

Application range of 90% of lightly burned magnesia powder:

Raw materials for making ceramics: 90% of lightly burned magnesia powder can be used to make ceramics and enamels, which can reduce the sintering temperature.

Metal processing: light burned magnesium powder can be used for desulphurization and deoxidation in metal processing to improve the purity and quality of metal.

In short, 90% of the applications of light-burned magnesia powder mainly cover the fields of flame retardants, metal processing, chemical reactants, powder metallurgy and ceramic manufacturing.

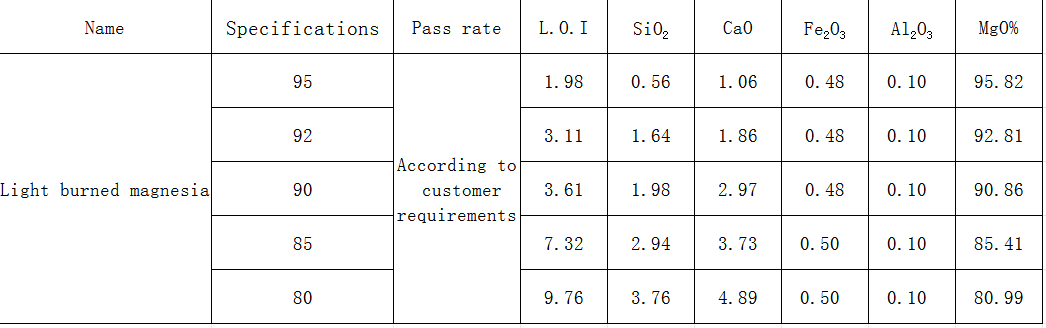

The parameters of lightly burned magnesia powder are as follows:

The parameters of lightly burned magnesia powder are as follows:

Raw materials for making anti-corrosion coatings:

Because magnesium has good corrosion resistance, light burned magnesium powder can be added to the coating to improve the corrosion resistance of the coating. In addition, light burned magnesia powder can also increase the gloss and hardness of the coating and make it more beautiful and durable.

About us.

The group company held a meeting of all production and technical personnel, technical personnel of various departments to discuss production technology, sum up previous work experience, improve product quality, and create first-class products. Committed to becoming a "trusted partner" of customers